Summary: Heat and humidity-resistant steel alloys provide essential durability for construction projects in Florida’s challenging climate. These specialized materials prevent corrosion, maintain structural integrity, and significantly extend the lifespan of infrastructure in high-temperature, moisture-rich environments. With proper material selection and implementation, your projects can withstand decades of exposure while reducing long-term maintenance costs. Spirit Metals offers expert consultation to help you select the optimal steel alloys for your specific construction needs.

The Hidden Threat to Your Construction Projects

You know the challenge all too well. Florida’s relentless humidity and scorching temperatures create the perfect storm for structural deterioration. Your carefully planned construction projects face an invisible enemy that silently attacks steel components, potentially compromising safety, increasing maintenance costs, and reducing overall lifespan. Without proper material selection, even the most meticulously designed structures can suffer premature failure, costing you valuable time, resources, and reputation.

In coastal regions where salt-laden air compounds these problems, the stakes become even higher. Standard steel simply won’t deliver the performance and longevity your clients demand, and your professional standards require. What you need is a solution specifically engineered to combat these harsh environmental conditions.

Understanding Heat and Humidity Resistant Steel Alloys

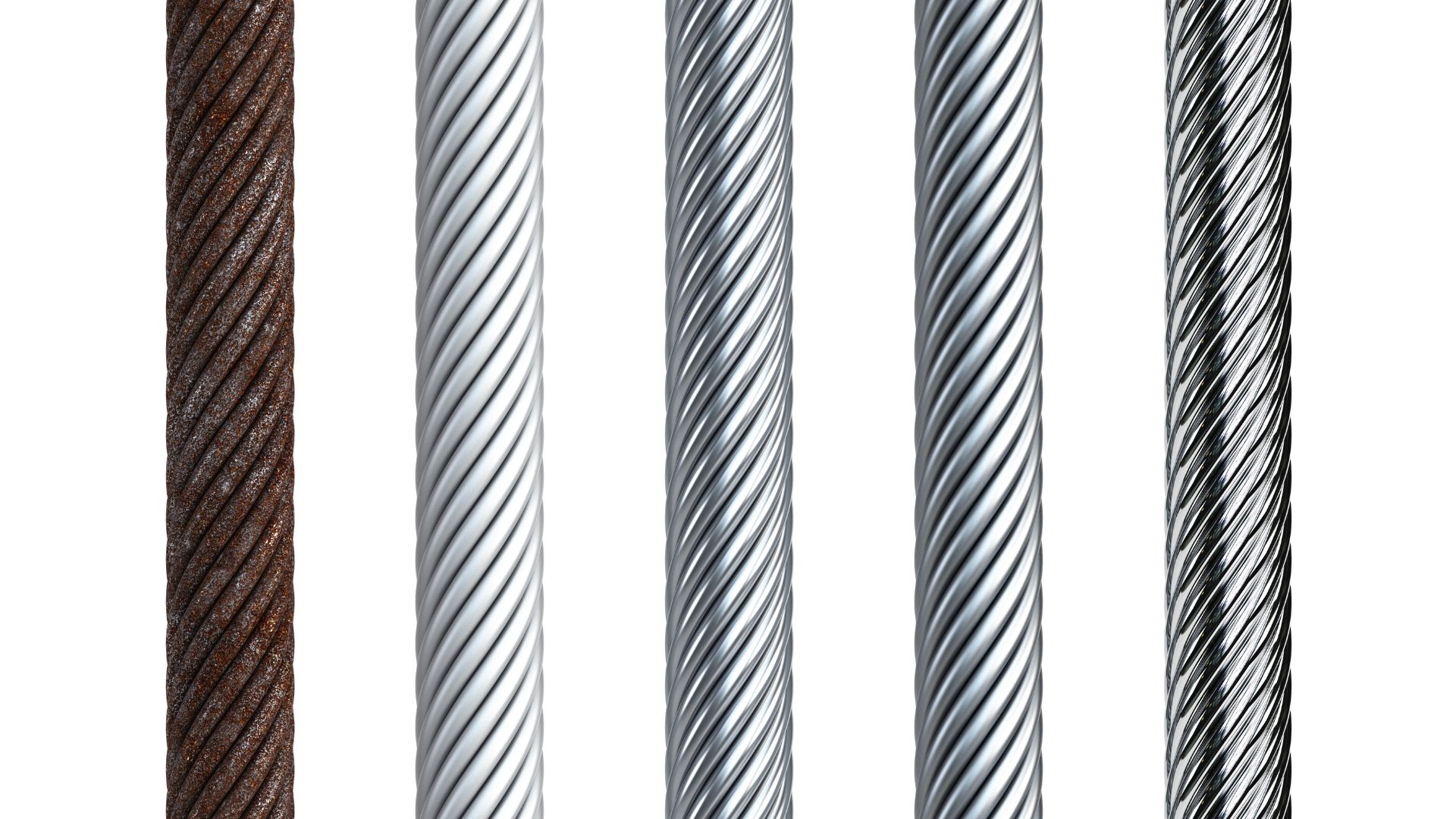

Steel alloys that are resistant to heat and humidity represent the pinnacle of metallurgical innovation for demanding environments. These specialized materials are formulated with precise blends of components -including chromium, molybdenum, and nickel – that confer inherent resistance to corrosion and oxidation. Unlike standard carbon steel, these alloys maintain their structural integrity and appearance even under extreme temperatures and high moisture levels.

The science behind heat and humidity-resistant steel alloys involves creating a protective oxide layer that prevents oxygen and moisture from penetrating the metal’s surface. This self-healing barrier acts as a shield against the electrochemical reactions that cause rust and other forms of deterioration. You can think of it as an immune system that continuously protects the steel from environmental attacks.

Types of Corrosion-Resistant Steel Alloys Ideal for Florida Projects

Various heat and humidity-resistant steel alloys offer different performance characteristics depending on your specific application requirements:

- Austenitic Stainless Steel: The 300-series (particularly 316 and 316L) provides excellent corrosion resistance in humid, coastal environments. The addition of molybdenum specifically enhances resistance to chloride attack, making these alloys ideal for structures near saltwater.

- Duplex Stainless Steel: Blending the best properties of austenitic and ferritic, these stainless steel alloys deliver superior strength and corrosion resistance. You’ll find them particularly valuable for structural components that face both mechanical stress and environmental challenges.

Related: Guide to Stainless Steel Grades and Their Applications

- Weathering Steel (Cor-Ten): Develops a stable, protective rust-like appearance that shields the underlying material from further corrosion. This self-protecting characteristic makes it suitable for certain architectural and structural applications where aesthetics and durability must coexist.

Keep Reading: The Advantages of Weathering Steel for Coastal Projects: Durability Meets Design

- High-Performance Low-Alloy Steels: Engineered with small amounts of copper, chromium, and nickel to enhance atmospheric corrosion resistance while maintaining excellent mechanical properties. These alloys offer an excellent balance of performance and cost-effectiveness for many Florida construction projects.

The Critical Applications of Heat and Humidity Resistant Steel Alloys

Understanding where and how these specialty alloy and metals deliver their greatest value helps you maximize their impact on your projects. The following applications represent areas where these specific steel alloys consistently demonstrate superior performance in Florida’s demanding climate.

Structural Components in Commercial Building

In commercial construction, you face unique challenges when building in Florida’s climate. Heat and humidity-resistant steel alloys prove invaluable for exposed structural elements, roofing systems, and exterior cladding. These materials ensure your buildings maintain both aesthetic appeal and structural integrity despite years of environmental exposure.

For example, in Jacksonville’s riverfront developments, structures using 316L stainless steel for exterior support elements have shown virtually no degradation after decades of service, whereas conventional materials have required replacement within 10-15 years. This demonstrates the remarkable long-term value these specialized alloys provide.

Bridge Construction and Maintenance

Florida’s numerous waterways necessitate extensive bridge infrastructure, much of which faces the dual challenge of humidity and salt exposure. You’ll find heat and humidity-resistant steel alloys essential for components like cable stays, expansion joints, and structural supports. These materials dramatically extend service life while reducing maintenance frequency and costs.

The Sunshine Skyway Bridge serves as an excellent example of how these specialty alloys and metals perform in real-world conditions. Components manufactured from specialized duplex stainless steel have demonstrated exceptional durability despite constant exposure to Tampa Bay’s harsh marine environment.

Manufacturing Facilities

Your manufacturing operations require materials that can withstand not only Florida’s climate but also thermal cycling during processing and potential chemical exposure. Heat and humidity-resistant steel alloys maintain dimensional stability and structural integrity even under these demanding conditions, ensuring continuous operation and worker safety.

In Brooksville’s manufacturing sector, facilities that use high-temperature-resistant alloys for support structures and equipment frames have reported significantly reduced maintenance requirements and improved operational reliability compared to those using conventional steel.

Roadway Infrastructure

From guardrails to support structures for signage and lighting, roadway construction in Florida demands materials that resist corrosion without requiring frequent maintenance. Heat and humidity-resistant steel alloys provide the durability and safety your projects require while reducing lifetime ownership costs for transportation authorities.

Also On Our Blog: Avoiding Inspection Delays with ASTM-Approved Steel Beams

Selecting the Right Steel Alloys for Your Project

Making an informed decision about which heat and humidity-resistant steel alloys are right for your project requires a systematic evaluation of multiple factors specific to your project. This methodical approach ensures you achieve the optimal balance of performance, durability, and cost-effectiveness for your unique application requirements.

Environmental Factors Assessment

You must carefully evaluate the specific environmental challenges your structure will face:

- Proximity to Saltwater: Structures within 5 miles of coastlines require alloys with enhanced chloride resistance.

- Temperature Variations: Consider both ambient temperature fluctuations and any process-related thermal cycling.

- Rainfall and Humidity Patterns: Areas with higher annual precipitation may require more corrosion-resistant grades.

- UV Exposure: Some alloys perform better under Florida’s intense sunlight.

Performance Requirements Analysis

Beyond environmental resistance, your material selection should consider:

- Load-Bearing Capacity: Ensure the alloy provides adequate strength for your structural requirements.

- Fatigue Resistance: Structures subject to cyclic loading need materials with superior fatigue properties.

- Expected Service Life: Match alloy performance to your project’s intended lifespan.

- Aesthetic Considerations: Some heat and humidity-resistant steel alloys maintain their appearance better than others.

Cost-Benefit Evaluation

While heat and humidity-resistant steel alloys typically represent a higher initial investment than standard materials, you’ll benefit from substantial long-term advantages:

- Reduced Maintenance Requirements: Less frequent repairs and replacements mean lower lifetime costs.

- Extended Service Life: Properly selected alloys can double or triple the functional lifespan of structures in Florida’s climate.

- Improved Safety and Reliability: Structures maintain their integrity over time, reducing the risk of failure.

- Enhanced Sustainability: Longer-lasting materials reduce resource consumption and construction-related disruptions.

Related: Why Steel’s Extended Life-Cycle Makes It The Most Sustainable Building Material

Implementation Best Practices for Maximum Value

Even the highest quality materials require proper handling and installation to deliver their full performance potential. Following industry-proven best practices ensures that your heat- and humidity-resistant steel alloys deliver maximum value throughout their service life.

Fabrication Considerations

When working with specialty steel alloys, you should observe these important fabrication practices:

- Proper Cutting Techniques: Use tools and methods specifically recommended for the alloy grade to prevent thermal damage and contamination.

- Welding Protocols: Follow alloy-specific welding procedures to maintain corrosion resistance in heat-affected zones.

- Surface Treatment: Properly finish surfaces to optimize corrosion resistance and appearance.

- Contamination Prevention: Avoid contact with carbon-steel tools, as they can transfer particles and compromise corrosion resistance.

Installation and Maintenance Strategies

To maximize the performance of heat and humidity-resistant steel alloys in your projects:

- Galvanic Isolation: Prevent contact between dissimilar metals that can accelerate corrosion through galvanic action.

- Drainage Design: Ensure structures allow complete water drainage to prevent standing moisture.

- Inspection Schedule: Establish regular visual inspections to identify and address any issues early.

- Cleaning Protocols: Implement periodic cleaning appropriate to the specific alloy and environment.

Success Stories: Thriving Florida Projects with Specialty Steel Alloys

A Fort Myers commercial development incorporated 2205 duplex stainless steel for its structural framework and exterior elements. After five years in service, including exposure to Hurricane Ian in 2022, the structure shows no signs of corrosion or degradation, while neighboring buildings with conventional materials required significant repairs.

In Jacksonville’s industrial corridor, manufacturing facilities constructed with heat and humidity-resistant steel alloys have demonstrated exceptional durability despite exposure to both coastal humidity and process-related thermal cycling. Maintenance costs for these facilities run approximately 40% lower than industry averages for similar structures built with conventional materials.

Partner with Spirit Metals for Your Heat and Humidity-Resistant Steel Alloy Needs

At Spirit Metals, we specialize in providing the highest quality heat and humidity-resistant steel alloys for Florida’s most demanding construction environments. Our extensive experience serving the Sunshine State’s commercial building, bridge construction, manufacturing, and roadway infrastructure sectors gives us unmatched insight into the specific challenges you face.

You can rely on our team to help you select the optimal materials for your project requirements, ensuring maximum performance, durability, and value. With our strategic locations throughout Central Florida and along both coasts, we provide prompt delivery and exceptional service from Jacksonville to Fort Myers and everywhere in between.

Contact our metallurgical experts today to discuss your specific heat and humidity-resistant steel alloy needs and discover how we can help you build structures that stand the test of time in Florida’s challenging climate.