When it comes to precision manufacturing, understanding the differences between water jet vs laser cutting for metal fabrication can help you make the right choice for your next project. As a professional in the construction and manufacturing industry, you need cutting solutions that deliver exceptional quality while meeting your specific material requirements and project timelines.

At Spirit Metals, Florida’s premier supplier of structural steel and specialty alloys, we’ve helped countless clients across Jacksonville, Tampa, and throughout Florida’s eastern and western coasts make informed decisions about the best cutting technologies for their precise needs.

Understanding the Fundamentals of Water Jet vs Laser Cutting for Metal Fabrication

Water jet vs laser cutting for metal fabrication represents two distinct approaches, each with unique operational principles that determine their suitability for different applications. Water jet cutting utilizes high-pressure water mixed with an abrasive material, typically garnet, to erode through metal with remarkable precision. Water cutting generates no heat, which means the metal’s structural integrity and properties remain completely unchanged throughout the cutting process.

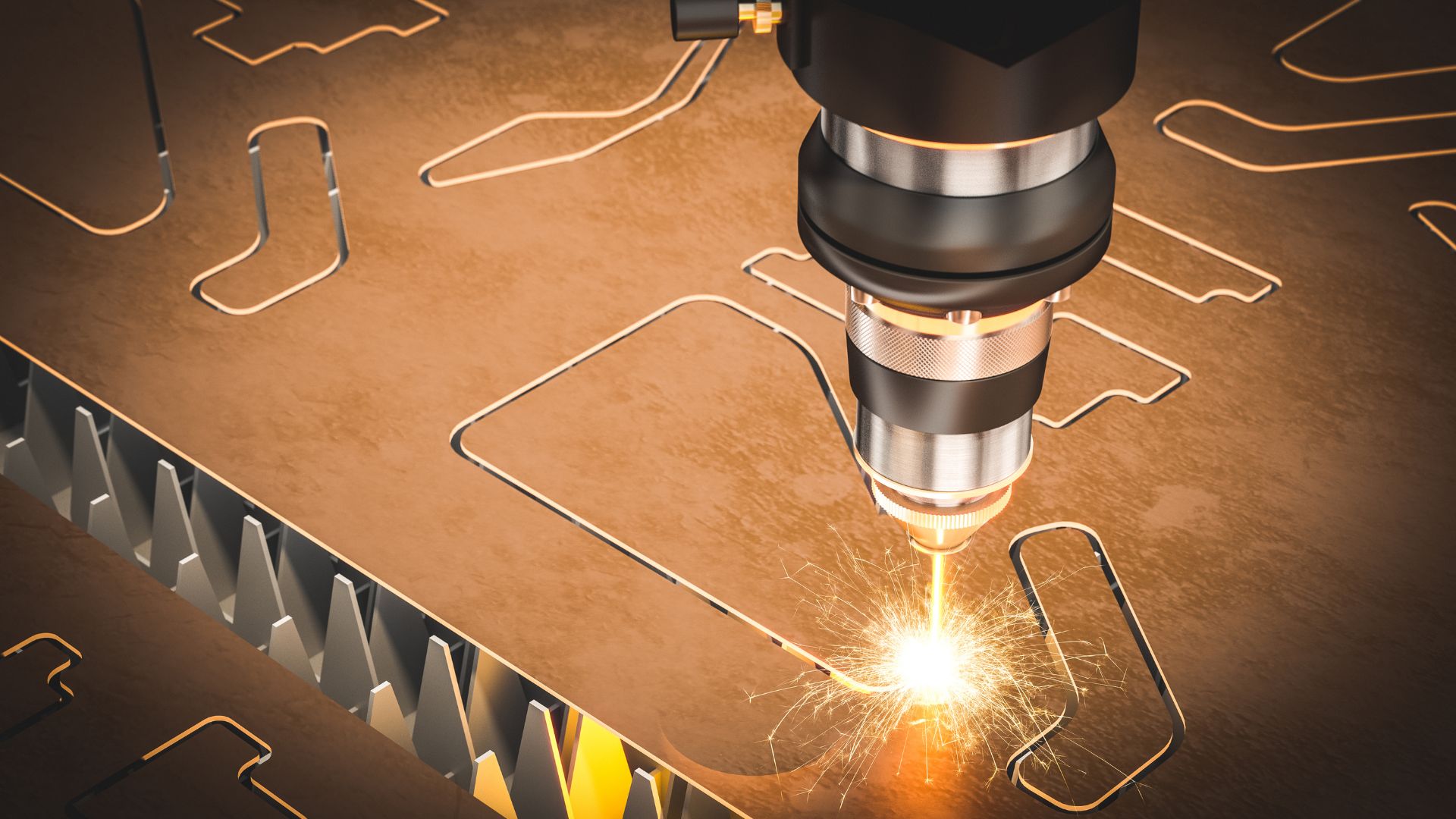

On the other hand, laser cutting focuses a beam of light that generates intense heat to melt, burn, or vaporize metal along a precisely controlled path. You should consider laser cutting when your projects demand extremely fine detail work on thinner metal sheets, as the technology excels at producing intricate patterns and designs with remarkably clean edges.

Material Compatibility Considerations

The type of metal you’re working with plays a major role in determining whether water jet vs laser cutting for metal fabrication is the optimal choice. Water jet cutting demonstrates remarkable versatility across virtually all metals, including structural steel, aluminum, copper, brass, and specialty alloys that might otherwise be challenging to cut. Water jet technology can efficiently process materials of significant thickness, up to several inches, making it ideal for heavy-duty structural components for bridge construction or commercial buildings throughout Central Florida.

Laser cutting, while more limited in material thickness capacity (typically under 1 inch for most metals), delivers exceptional results on carbon steel, stainless steel, and aluminum. When you’re working on projects requiring both thick and thin components, you’ll benefit from working with a fabrication partner like Spirit Metals that can offer both technologies to optimize your entire production process.

Read Also: Fun Facts about Steel and what you may not know!

Precision and Accuracy Considerations

When evaluating water jet vs laser cutting for metal fabrication, laser cutting technology typically achieves tolerances as tight as ±0.001 inches, making it exceptionally well-suited for projects demanding extremely fine detail work and intricate geometries. Water jet cutting maintains impressive accuracy as well, with standard tolerances of approximately ±0.005 inches, though this can vary depending on material thickness and specific equipment capabilities. Both technologies offer superior edge quality compared to traditional mechanical cutting methods. However, you’ll notice laser cutting typically produces edges that require minimal to no secondary finishing, potentially saving you valuable production time.

Speed and Production Efficiency Considerations

Production speed differences between water jet vs laser cutting for metal fabrication are a big factor in your decision-making process. Laser cutting generally offers significantly faster cutting speeds, especially when working with thin to medium-thickness sheets of common metals like steel and aluminum. Water jet cutting operates at comparatively slower speeds, particularly when processing thicker materials or extremely hard alloys, as the erosion process simply requires more time to penetrate and cut through substantial metal sections.

You should factor this speed difference into your project planning, especially for large structural components that might benefit from the water jet’s ability to cut thick materials despite the longer processing time. When your project involves a mix of component thicknesses, working with Spirit Metals gives you access to both technologies, allowing you to optimize each component’s production method.

Environmental Factors for Water Jet vs Laser Cutting

When selecting between water jet vs laser cutting for metal fabrication, considering the environmental and safety implications aligns with both regulatory requirements and sustainable business practices throughout Florida.

Water jet cutting produces no hazardous fumes or airborne contaminants during operation, as the process relies solely on water and garnet abrasives. The absence of heat in the water jet process eliminates fire hazards and reduces workplace safety risks associated with handling hot materials. Laser cutting, while incredibly precise, does generate some fumes and particulates that require proper ventilation and filtration systems to maintain air quality in your facility.

Edge Quality and Finishing Requirements

When comparing the edge quality of water jet vs laser cutting for metal fabrication, laser cutting typically produces exceptionally clean, smooth edges with minimal burring on most metals under 1 inch. Laser-cut edges exhibit minimal taper, creating precise mating surfaces for welding or assembly applications.

Water jet cutting produces slightly rougher edge textures compared to laser cutting, though the quality remains superior to many conventional cutting methods. You should note that water jet technology creates absolutely no heat-affected zone, preserving the material’s properties right to the cut edge. Water jets offer a major advantage when working with hardened metals or components subject to high stress in applications.

Related: Types of Welding for Different Metals: How to Choose the Right Method for Your Project

Complex Geometries and Design Flexibility

The ability to produce complex geometries varies significantly between water jet and laser cutting technologies. Laser cutting excels at producing extremely intricate patterns, fine details, and complex internal features with exceptional precision, making it ideal for decorative elements and parts requiring numerous small holes or slots.

Water jet cutting, while not quite as precise at fine detail work, offers remarkable flexibility for cutting complex shapes through materials of virtually any thickness. The water jet’s ability to begin cutting at any point on the material also allows for efficient nesting when producing multiple parts from a single sheet.

Cost Effectiveness: Comparing Water Jet vs Laser Cutting for Metal Fabrication

Understanding the cost implications of water jet vs laser cutting for metal fabrication helps you make economically sound decisions for your Central Florida construction or manufacturing projects without compromising on quality. Laser cutting typically offers lower per-part costs when producing large quantities of thin metal components, as its faster cutting speeds reduce labor costs and increase throughput for standard materials like carbon steel and aluminum. Water jet cutting, while potentially slower and more labor-intensive, eliminates many secondary operations that might otherwise be necessary with thermal cutting methods.

Contact Spirit Metals Today for Expert Advice on Water Jet vs Laser Cutting for Metal Fabrication

Your construction or manufacturing project in Central Florida deserves the highest quality materials and fabrication services. Spirit Metals stands ready to provide expert guidance on whether water jet vs laser cutting represents the optimal solution for your specific metal fabrication needs. You can reach our knowledgeable team today at 813-444-2022 for Tampa/St. Pete area projects, or 561-501-0056 for South Florida inquiries. Our specialists will take the time to understand your project requirements, recommend the most appropriate cutting technology, and provide competitive pricing that reflects both quality and value.

Don’t compromise on precision or material integrity. Partner with Florida’s premier supplier of structural steel and specialty alloy and experience the difference that our commitment to honesty, integrity, and excellence makes in every customer relationship.