Choosing the appropriate diamond plate thickness is crucial for ensuring your structural projects maintain safety, durability, and cost-effectiveness. Whether you’re tackling a commercial project, a bridge, or custom fabrication work, understanding the nuances of diamond plate thickness can be the difference between project success and costly failures.

At Spirit Metals in Florida, USA, we’ve seen countless local and national contractors struggle with material selection, often resulting in project delays, budget overruns, or even safety concerns when incorrect specifications are chosen.

The Real Challenges of Diamond Plate Selection

Have you ever installed checker plate flooring only to discover it buckles under expected loads? Or, you may have overspecified the tread plate thickness, unnecessarily increasing project costs. You’re not alone. Many construction professionals and fabricators face challenges when selecting these materials, including:

- Balancing strength and weight: Heavier isn’t always better, especially when factoring in structural load limitations and installation difficulties.

- Budget constraints: Overspecifying diamond plate thickness can directly impact your bottom line and make projects financially unfeasible.

- Application-specific requirements: Different environments and applications demand different checker plate specifications that aren’t always obvious.

- Regulatory compliance: Failing to meet minimum thickness requirements for specific applications can result in failed inspections and costly rework.

Understanding Diamond Plate Thickness and Its Importance

Diamond plate, also referred to as tread plate or checker plate, is characterized by its distinctive raised diamond pattern, which provides both aesthetic appeal and practical slip resistance. However, the thickness is what truly determines its performance in real-world applications.

The diamond plate thickness significantly impacts several critical factors:

- Load capacity: The thickness directly correlates to how much weight the material can support without deformation. This is especially important in flooring, ramps, and walkway applications.

- Durability: Thicker tread plate generally offers greater resistance to wear, impact damage, and environmental stressors. In high-traffic commercial applications, selecting the correct thickness is crucial for ensuring longevity.

- Weight considerations: Every increase in checker plate thickness adds weight to your structure, potentially impacting foundation requirements or requiring additional structural support.

According to the Steel Market Development Institute, selecting the proper tread plate thickness should follow established engineering principles based on load requirements and application specifications.

Common Diamond Plate Thickness Options and Their Applications

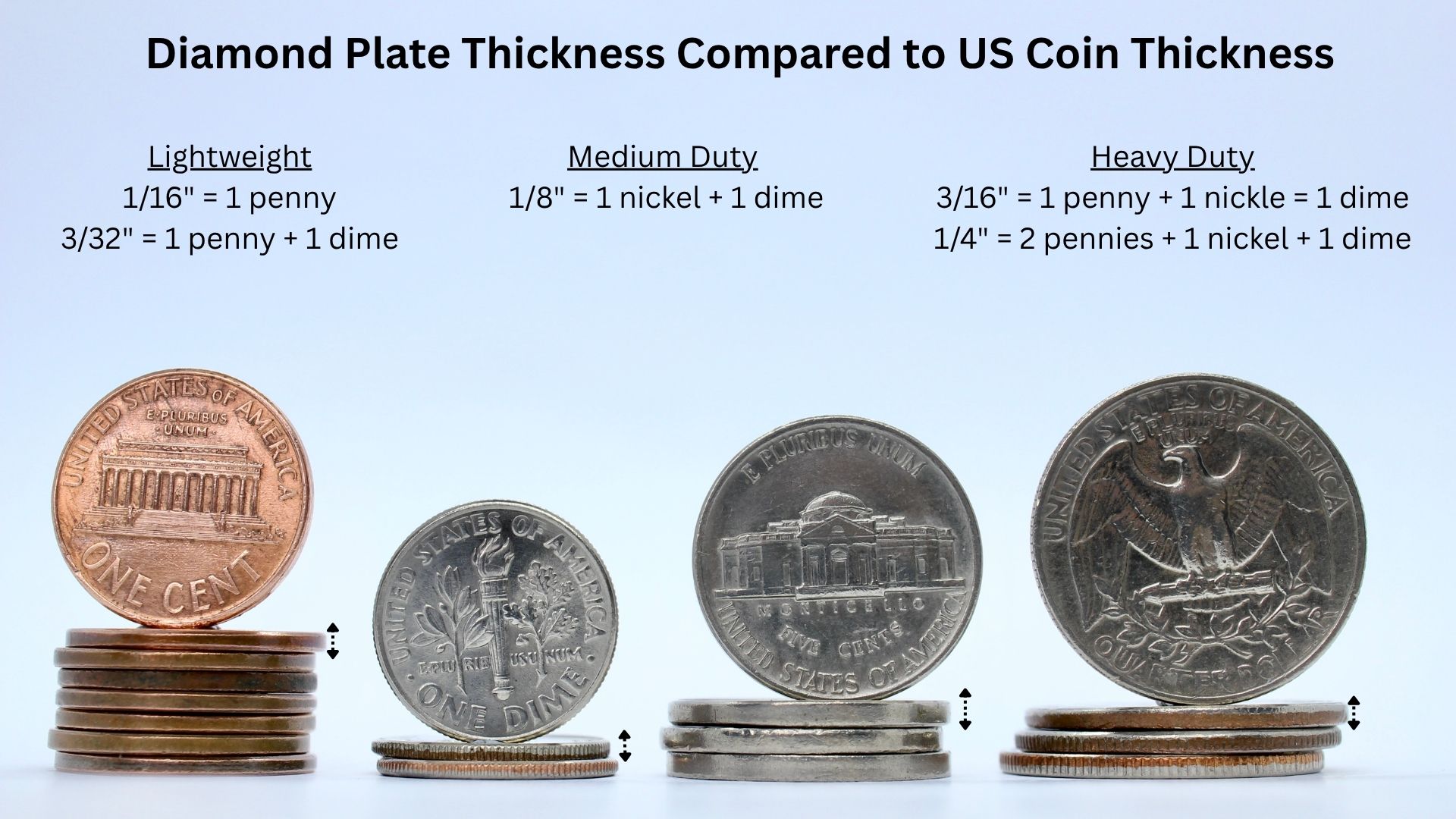

When selecting diamond plate thickness, you’ll typically encounter measurements ranging from 1/16″ (1.5mm) to 1/4″ (6.35mm) for most commercial applications. Each serves specific purposes:

Lightweight (1/16″ – 3/32″)

This checker plate thickness is ideal for:

- Decorative applications: When appearance matters more than structural support

- Light-duty wall protection: Areas with minimal impact exposure

- Automotive applications: Where weight considerations are paramount

Medium-Duty (1/8″)

This versatile tread plate thickness (slightly thicker than a dime and a quarter stacked) works well for:

- Commercial walkways: Areas with regular foot traffic

- Equipment covers: Protecting machinery while allowing easy access

- Truck beds and trailers: Balancing durability with weight constraints

Heavy-Duty (3/16″ – 1/4″)

This substantial diamond plate thickness is necessary for:

- Loading docks: Where heavy equipment and frequent impacts occur

- Industrial flooring: High-traffic areas requiring maximum durability

- Bridge components: Meeting rigorous infrastructure requirements

Research from the American Institute of Steel Construction indicates that properly matching checker plate thickness to application requirements not only ensures safety but can extend service life by up to 40% compared to improperly specified materials.

You Might Like: Fun Facts about Steel and What You May Not Know!

How to Select the Right Diamond Plate Thickness for Your Project

Determining the optimal diamond plate thickness involves careful consideration of multiple factors:

Assess Load Requirements

Calculate both static and dynamic loads the material will need to support.

- Static loads: Permanent weights like equipment or structures

- Dynamic loads: Moving weights like vehicles, people, or vibrating machinery

- Impact loads: Sudden forces from dropped objects or equipment

Consider Environmental Factors

Different environments can affect performance requirements.

- Outdoor exposure: May require thicker material to account for corrosion allowance

- Chemical exposure: Certain environments may necessitate thicker tread plate to maintain structural integrity over time

Evaluate Installation Methods

The checker plate thickness you select must be compatible with your intended installation approach.

- Welding requirements: Thicker plates may require special welding procedures

- Mechanical fastening: Different thicknesses work best with specific fastener types

- Support spacing: Thinner diamond plate requires more frequent structural supports

Review Regulatory Requirements

Many applications have minimum thickness requirements specified by building codes, industry standards, and safety regulations.

Common Mistakes When Selecting Diamond Plate Thickness

Even experienced professionals sometimes make errors when specifying the thickness of the tread plate. Being aware of these common pitfalls can help you avoid costly mistakes:

- Assuming thicker is always better: While it might seem logical that a thicker checker plate is always superior, over-specification wastes resources and can create unnecessary weight issues.

- Ignoring deflection calculations: Many professionals focus solely on load-bearing capacity without considering deflection, which refers to the extent to which the material will bend under load. Even if a specific diamond plate thickness can technically support the weight, excessive deflection can create unsafe conditions.

- Failing to account for future needs: Your current application requires only minimal thickness, but considering potential future uses might justify selecting a slightly heavier option.

- Overlooking substructure requirements: The tread plate thickness you select determines the type of support structure required underneath. A thinner plate requires more frequent supports, which may not be practical in some applications.

Related: What Is Galvanizing and When Is It Recommended?

Industry-Specific Diamond Plate Thickness Recommendations

Different sectors have developed standard practices regarding checker plate thickness based on decades of real-world experience:

Commercial Construction

- Walkways and platforms: 1/8″ to 3/16″ depending on span and load

- Decorative wall protection: 1/16″ to 3/32″ for visual impact with minimal weight

Transportation Sector

- Truck beds and trailers: 1/8″ to 3/16″, balancing durability with weight considerations

- Loading ramps: 3/16″ to 1/4″ to handle rolling loads and impacts

Industrial Environments

- Platform flooring: 3/16″ to 1/4″ for heavy equipment areas

- Catwalks and mezzanines: 1/8″ to 3/16″ depending on span distance

Marine Applications

- Dock surfaces: Minimum 3/16″ with appropriate marine-grade alloys

- Gangways and ramps: 3/16″ accounting for both load and corrosion allowance

Making the Final Decision on Diamond Plate Thickness

After considering all factors, we recommend this straightforward approach:

- Document your requirements: Create a precise specification including maximum expected loads, environmental exposures, and service life expectations.

- Consult with experts: At Spirit Metals, our team has decades of experience helping Florida contractors select the right checker plate thickness for specific applications.

- Request samples: Sometimes, seeing and handling different tread plate thickness options can help clarify which one is most suitable for your application.

- Consider maintenance implications: Different thicknesses may have different maintenance requirements over time. Thinner materials might need more frequent inspection or earlier replacement in high-wear applications.

Why Spirit Metals is Your Trusted Partner

At Spirit Metals, we support Florida’s construction and fabrication professionals throughout the entire process:

- Extensive inventory: We offer a broad selection of diamond plate in various thicknesses to meet immediate project needs across Central Florida, Jacksonville, and from Brooksville to Ft. Myers.

- Custom cutting and fabrication: Beyond providing raw materials, we can deliver checker plate cut to your specifications, saving you time and reducing waste.

- Technical expertise: With practical expertise in tread plate thicknesses, our team can assist you in making informed choices tailored to your project requirements.

- Quality assurance: Every product we offer meets or exceeds industry benchmarks for accuracy and material quality, ensuring a solid start for your project.

Conclusion: Make the Right Choice for Project Success

Selecting the appropriate diamond plate thickness is more than a technical decision—it’s an investment in the success of your project. The right choice strikes a balance between performance requirements, budget constraints, and long-term durability.

For your next project requiring diamond plate, remember that thickness selection should never be an afterthought. By identifying your exact needs and working alongside Spirit Metals, Florida’s experienced and knowledgeable plate supplier, your applications will deliver consistent results over their entire lifespan.

Ready to discuss your specific requirements? Contact Spirit Metals today, and let our team of experts help you select the perfect materials for your next construction or fabrication project.