When planning your next construction project, learning how to choose heavy square tubing can make the difference between a structure that barely meets requirements and one that exceeds expectations. Square tubing serves as the backbone for countless commercial and industrial applications, from building frameworks to equipment supports. As a professional in the construction, manufacturing, or roadway development industry, you understand that material selection directly impacts project success, safety compliance, and budget management.

At Spirit Metals, we supply high-quality structural steel and specialty alloys throughout Central Florida, from Jacksonville down the eastern coast and Brooksville to Ft Myers on the western coast. Our expertise in providing the right heavy square tubing and other metal products has made us a trusted partner for professionals in commercial building, bridge work, and construction industries who need reliable materials to complete their projects.

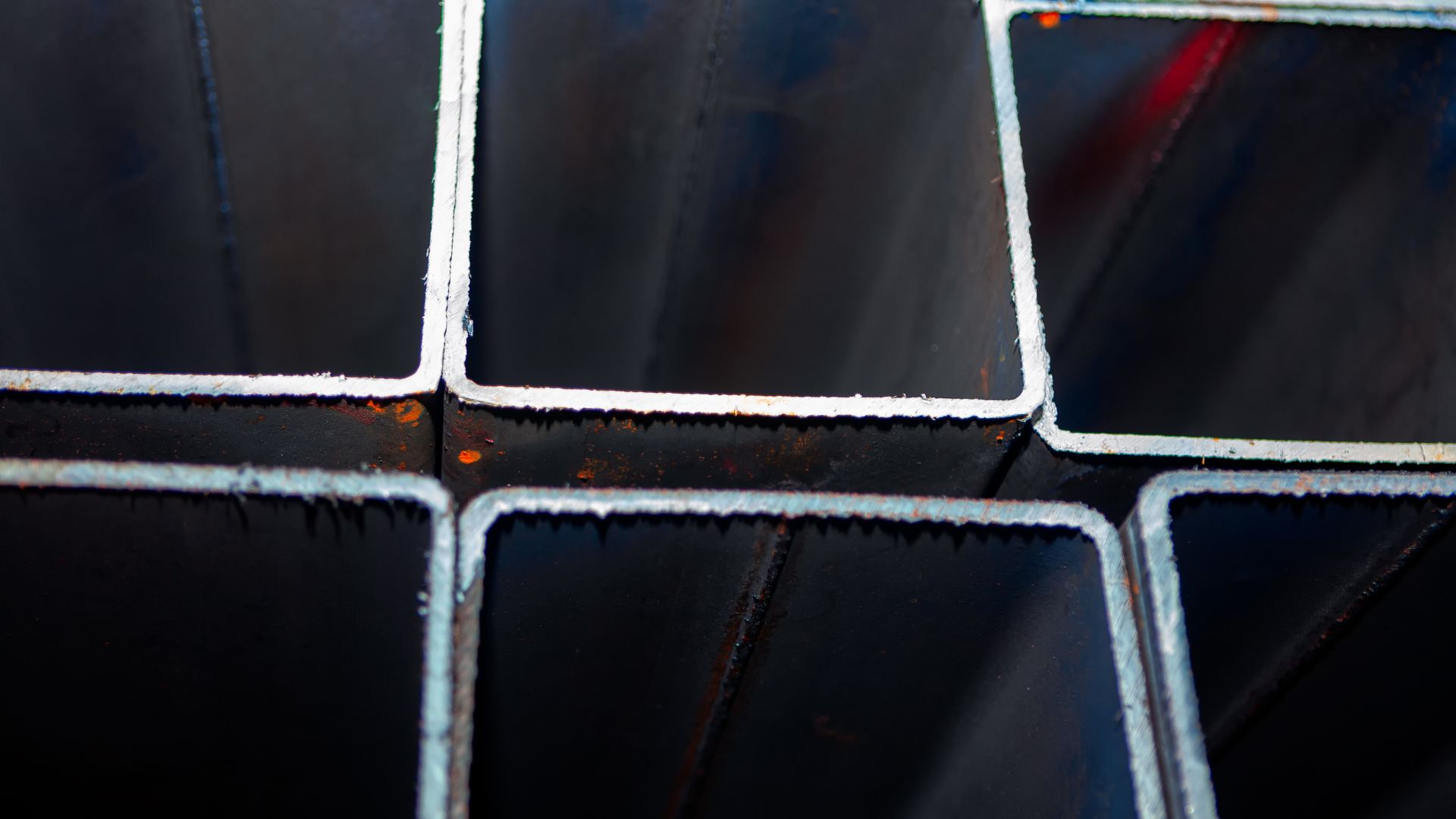

Heavy Square Tubing Specifications

Square and rectangular tubing is categorized by outside dimensions, wall thickness, material grade, and finishing options. When examining product specifications, the dimensions are typically listed as the outside measurement in inches, followed by the wall thickness. For example, a 4×4×1/4″ designation indicates a square tube with 4-inch sides and 1/4-inch wall thickness. Material grades, such as A500 Grade B or A513, indicate the steel’s composition, manufacturing process, and mechanical properties. Heavy square tubing also comes in specific finishing options like galvanization for corrosion resistance or prime coating for painting preparation.

How to Choose Heavy Square Tubing Based on Load Requirements

Determining the load requirements is your first critical step when you choose heavy square tubing for structural applications. Begin by calculating both dead loads (permanent weight) and live loads (variable weights from occupancy, equipment, or environmental factors) that your structure must support. Heavy square tubing with thicker walls provides greater load-bearing capacity for vertical compression applications, while larger dimensions improve resistance to bending under horizontal loads.

When selecting tubing for applications with dynamic loads, you’ll need to account for fatigue considerations by potentially upgrading to higher-grade materials or larger dimensions. Multi-directional stress patterns require careful analysis, as square tubing responds differently to forces applied from various angles, potentially necessitating reinforcement strategies for complex loading scenarios.

Material Selection: Comparing Steel Grades for Square Tubing

When you choose heavy square tubing, the steel grade you select has a significant impact on its performance. A500 Grade B steel, the industry standard for structural tubing, offers excellent weldability and strength with a minimum yield strength of 46,000 psi, making it suitable for most general construction applications.

When your project demands higher strength-to-weight ratios, consider A500 Grade C, which provides a minimum yield strength of 50,000 psi while maintaining good fabrication characteristics. For applications exposed to high moisture or corrosive materials, galvanized tubing or stainless steel options provide enhanced protection. High-strength low-alloy (HSLA) steel tubing can also be used to offer superior strength in specialized applications where weight reduction is vital.

Read Also: Benefits of Heavy Square and Rectangular Tubing in Fabrication

Dimensional Considerations When You Choose Heavy Square Tubing

Selecting the appropriate dimensions is crucial when you choose heavy square tubing for your specific application:

- The outside dimensions directly affect the tubing’s ability to resist bending forces, with larger profiles providing greater rigidity across spans.

- Wall thickness determines compression strength and puncture resistance, with heavier walls offering superior performance in high-stress applications.

- Length requirements must account for connection methods, as longer spans may require higher-strength materials to prevent deflection.

For applications where weight is a concern, optimizing the balance between outside dimensions and wall thickness allows you to achieve the necessary strength while minimizing the overall mass of your structure.

Fabrication Compatibility: Welding and Connection Considerations

When you choose heavy square tubing, consider how it will integrate with your fabrication processes and connection methods. Weldability varies between steel grades. A500 tubing generally offers excellent welding characteristics, while specialty alloys may require specific techniques or pre-heating to achieve proper fusion.

Connection designs will significantly influence material selection, as bolted connections typically require reinforcement plates, while welded joints depend on proper edge preparation and post-weld heat treatment. Corner joints present unique challenges when working with square tubing, often requiring precise cutting and fitting to achieve proper load transfer through the connection point.

Your cutting methods will vary based on material thickness, with thinner walls suitable for shearing or cold sawing, while thicker heavy-gauge tubing may require plasma or oxy-fuel cutting followed by edge preparation for joining. When designing connections, always consider how loads will transfer through the joint, as concentrated stresses can lead to premature failure.

Surface Finish and Corrosion Protection Options

Make sure to select the appropriate surface treatments when you choose heavy square tubing:

- Bare steel tubing offers the lowest initial cost, but it requires the prompt application of protective coatings to prevent corrosion in most environments.

- Hot-dip galvanized tubing provides excellent long-term protection for outdoor applications through a zinc coating that sacrifices corrosion to protect the underlying steel.

- Powder coating combines corrosion resistance with aesthetic customization, allowing you to match your structural elements to architectural designs while providing a durable finish resistant to chipping and fading.

- For specialized applications, consider combination systems where galvanized tubing receives additional powder or paint coating, offering maximum protection in extremely corrosive environments like coastal regions or industrial settings.

When selecting a finish, always evaluate the specific environmental exposures your structure will face, including UV radiation, salt spray, chemical exposures, and abrasion potential, as these factors will determine the appropriate protection system for your investment.

Related: What Is Galvanizing and When Is It Recommended?

Budget Considerations Without Compromising Quality

Managing project costs effectively requires understanding how different factors impact pricing when you choose heavy square tubing. Material grade significantly influences price, with standard A500 tubing typically offering the most economical option while specialty alloys or stainless steel command premium prices that may be justified by specific performance requirements.

Quantity purchasing often provides substantial savings, making it worthwhile to consolidate orders and standardize dimensions across projects when possible to achieve volume discounts. Transportation costs can be significant, particularly for long lengths or large quantities, so consider working with regional suppliers like Spirit Metals that offer delivery services throughout Florida to minimize these expenses.

Partner with Experts to Choose Heavy Square Tubing

Leveraging professional expertise can significantly improve outcomes when you need to choose heavy square tubing for complex applications. Engineering consultation may be beneficial for projects with unusual loading conditions, critical safety requirements, or specialized performance needs that go beyond standard applications. Metal suppliers with deep industry experience, like Spirit Metals, offer valuable insights beyond simple product information, including fabrication recommendations, cost-saving alternatives, and availability forecasting that can prevent project delays.

Material testing services provide verification when your application has narrow performance tolerances or when using materials with an unestablished track record. When dealing with specialty applications, such as those in extreme environments, dynamic loading, or aesthetic architectural features, consider involving application specialists who understand the unique challenges these conditions present.

Contact Spirit Metals to Help You Choose Heavy Square Tubing for Your Next Project

The right structural materials serve as the backbone of your construction project, providing not just immediate compliance with design requirements but long-term reliability that protects your investment for decades to come. As you move forward with your project planning, remember that expert guidance from experienced suppliers can make the selection process more efficient and effective, potentially identifying opportunities for improvement that might otherwise be missed.

When you’re ready to choose heavy square tubing for your next construction project, Spirit Metals offers a comprehensive range of high-quality structural steel products, including square tubing in various dimensions, wall thicknesses, and material grades to meet your requirements. From standard structural applications to specialized requirements, we offer the products, expertise, and service you need to complete your projects successfully.

Don’t compromise on material quality for your structural components. Get in touch with Spirit Metals today for a quote and experience excellence in every aspect of your metal supply needs.