Summary: Custom steel bollards provide essential protection against vehicle impacts and security threats. These specialized barriers can be engineered to meet specific requirements for impact resistance, installation method, and aesthetics. With proper selection, fabricated steel safety bollards create effective security perimeters, protect infrastructure, and enhance pedestrian safety while maintaining accessibility and visual appeal.

The Vulnerability Challenge: Protecting What Matters Most

Your commercial property, manufacturing facility, or construction site faces daily threats from vehicle impacts, whether accidental or intentional. Without proper protection, a single collision can result in costly structural damage, equipment loss, business interruption, and injuries.

In Florida’s busy commercial environments, the risk is particularly acute. Heavy equipment moves constantly through warehouses and loading zones. Parking areas adjacent to buildings create collision hazards. Security threats require robust physical barriers against forced entry attempts.

Standard solutions often fail to address your specific requirements. Your unique property layout, operational needs, and aesthetic considerations demand a tailored approach to ensure protection without compromising functionality or visual appeal.

Understanding Custom Steel Bollards

Custom-fabricated bollards represent the pinnacle of site protection technology, offering tailored solutions for your specific security requirements. These robust vertical posts serve as physical barriers, preventing vehicle access to restricted areas, protecting structures, and enhancing site security.

Unlike standard options, custom steel bollards can be precisely engineered to meet your exact specifications regarding height, diameter, wall thickness, mounting method, and finish. This customization ensures optimal performance while complementing your property’s design elements.

The core strength of steel bollards fabricated to meet site requirements lies in their construction. Fabricated from high-grade structural steel with substantial wall thickness, these bollards provide exceptional impact resistance. Many designs incorporate concrete filling for additional mass and stability.

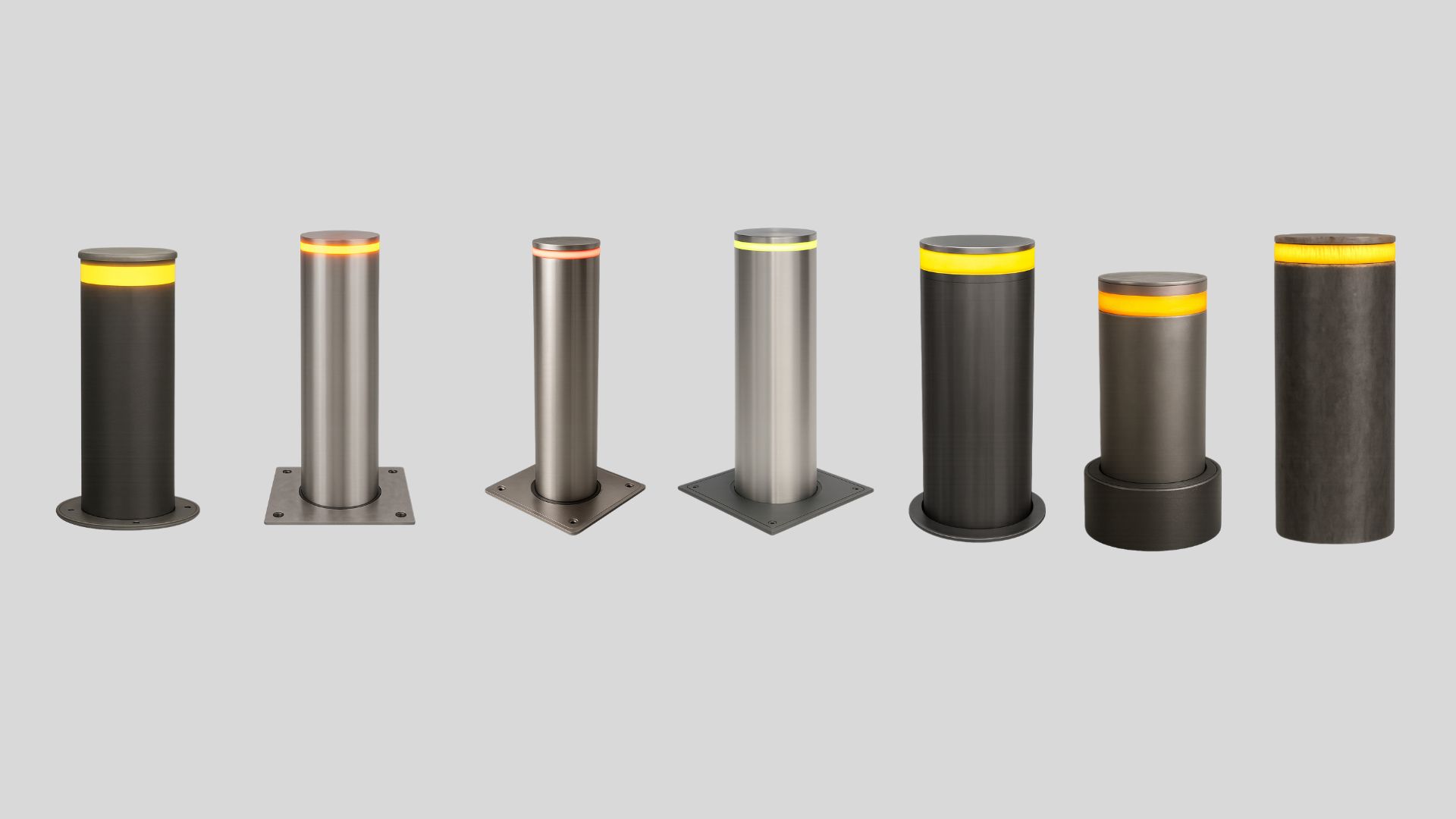

Types of Custom Steel Bollards for Different Applications

Understanding the various bollard configurations helps you select the optimal solution for your specific security and operational requirements.

- Fixed Embedded Bollards: Permanently installed in concrete foundations, these provide maximum impact resistance for high-security applications. Ideal for protecting critical infrastructure and building entrances.

- Surface-Mounted Bollards: Attached to existing concrete surfaces using heavy-duty anchors, these offer protection without extensive excavation. Perfect for retrofitting or where underground utilities prevent embedded installation.

- Removable Bollards: Feature locking mechanisms that allow authorized removal when vehicle access is needed. They provide security without permanently restricting access.

- Collapsible Bollards: Engineered with hinged bases that allow lowering when access is required. They provide flexible security for areas with occasional vehicle traffic needs.

- Decorative Bollards: Combine protection with architectural design elements to enhance aesthetic appeal while providing security.

You Might Like: Stainless vs Carbon Steel Flanges: Making the Right Choice for Your Florida Project

The Critical Applications of Precision-Fabricated Bollards

Knowing where custom steel bollards deliver their greatest value helps you maximize their impact on your property’s security profile. The following applications represent areas where these specialized barriers consistently demonstrate superior performance in Florida’s demanding environments.

Perimeter Security and Access Control

Made-to-order steel bollards excel at defining secure perimeters while controlling vehicle access points. Strategically placed bollards prevent unauthorized vehicle entry while allowing pedestrian access, creating a balanced security approach.

For facilities requiring periodic vehicle access, removable or collapsible bollards provide the perfect solution. Security personnel can easily grant access for deliveries or emergency responders, then restore protection afterward.

Building and Infrastructure Protection

Your facilities represent significant investments that deserve comprehensive protection. Custom steel bollards provide targeted defense for vulnerable elements:

- Storefront Protection: Prevent vehicles from breaching storefronts while maintaining an inviting appearance for customers.

- Loading Dock Safety: Guide vehicles safely while protecting dock doors, equipment, and personnel in tight spaces.

- Utility Protection: Shield critical infrastructure components, such as electrical transformers and gas meters, while maintaining maintenance access.

- Equipment Safeguarding: Create protective zones around valuable machinery to prevent costly damage and operational downtime.

Pedestrian Safety Enhancement

In areas where pedestrian and vehicular traffic converge, bollards create a clear separation that enhances safety:

- Walkway Protection: Prevent vehicles from encroaching into pedestrian spaces.

- Outdoor Gathering Areas: Protect patios, outdoor dining spaces, and public seating areas from vehicle intrusion.

- Building Entrances: Safeguard doorways and access points with high pedestrian traffic, particularly where parking areas are adjacent.

Selecting the Right Specialty Steel Bollards for Your Project

Making an informed selection of custom steel bollards requires a systematic evaluation of multiple factors specific to your project. This methodical approach ensures you achieve the optimal balance of performance, durability, and cost-effectiveness for your unique requirements.

Impact Resistance Requirements

The primary consideration for project-specific bollards is determining the level of impact resistance needed:

- Traffic Type Assessment: Evaluate the types of vehicles that might impact your bollards. Heavier vehicles require greater impact resistance.

- Speed Considerations: Higher speeds generate more impact force. Areas with faster-approaching vehicles require higher crash ratings.

- Risk Analysis: Consider both accidental and intentional impact scenarios. High-security applications may require compliance with certified crash-test standards.

- Crash Rating Selection: For critical security, specify bollards with appropriate ratings (M30, M40, or M50) indicating their ability to stop vehicles of specific weights at defined speeds.

Installation Environment Factors

Your site conditions significantly influence the specifications of custom steel bollards:

- Soil and Foundation Conditions: Embedded bollards require proper foundation design based on soil conditions.

- Surface-Mounting Requirements: Existing slabs must have sufficient thickness and reinforcement to support surface-mounted bollards.

- Underground Utilities: May restrict excavation, necessitating surface-mounted or shallow-foundation designs.

- Weather Exposure: Florida’s humid environment requires appropriate materials and finishes for long-term durability.

Related: Building with Heat and Humidity Resistant Steel Alloys in Demanding Environments

Operational and Aesthetic Considerations

Beyond pure performance specifications, consider how your bollards will function within your overall property:

- Access Requirements: Determine frequency of access needs and select appropriate mechanisms.

- Visual Integration: Choose custom colors, decorative sleeves, or architectural details that complement your property’s style.

- Visibility Requirements: Consider reflective tape, integrated lighting, or bright colors for low-visibility conditions.

- Maintenance Considerations: Select designs that facilitate easy upkeep while maintaining performance.

Implementation Best Practices for Custom Steel Bollards

Even the highest quality materials require proper handling and installation to deliver their full performance potential. Following industry-proven best practices ensures your custom-fabricated steel bollards provide maximum value throughout their service life.

Professional Design and Engineering

Start with expert design services to ensure your custom steel bollards meet all requirements:

- Site-Specific Analysis: Work with professionals who will evaluate your specific conditions and security needs.

- Engineering Calculations: Ensure proper structural engineering based on anticipated impact forces.

- Compliance Verification: Confirm designs meet relevant building codes and security standards.

- Documentation: Maintain comprehensive specifications and maintenance requirements.

Quality Installation Procedures

Proper installation of site-specific bollards is critical to their performance and longevity:

- Foundation Preparation: Ensure proper excavation depth, reinforcement, and concrete specifications.

- Precise Positioning: Maintain accurate spacing and alignment for proper coverage.

- Concrete Filling: When specified, ensure complete filling without voids.

- Surface Finishing: Apply protective coatings to ensure materials perform in Florida’s humidity.

You Might Like: Metal Fabrication Coping Cuts: The Smart Way to Boost Job-Site Efficiency

Ongoing Maintenance

Protect your investment with regular maintenance to ensure continued performance:

- Scheduled Inspections: Identify damage, corrosion, or foundation issues before they compromise the performance of your custom steel bollards.

- Impact Response: After any vehicle contact, inspect affected bollards for structural integrity.

- Surface Maintenance: Regularly clean and touch up protective finishes.

- Mechanism Testing: For removable or collapsible bollards, periodically test operating mechanisms.

Success Story: Florida Property Protected by Custom Steel Bollards

A Jacksonville commercial development implemented decorative bollards to protect its glass-fronted retail spaces while complementing the modern architectural design. Since installation, the property has prevented vehicle intrusions despite multiple instances where vehicles lost control in the adjacent parking area.

Partner with Spirit Metals for Your Fabricated Steel Bollard Needs

At Spirit Metals, we specialize in fabricating and processing steel and other metals for Florida’s commercial, industrial, and infrastructure projects. Our experience gives us insight into the specific challenges you face in protecting your valuable assets.

You can rely on our team to help you select the optimal bollard design for your requirements, ensuring maximum performance, durability, and value. With locations throughout Central Florida and along both coasts, we provide prompt delivery and exceptional service from Jacksonville to Fort Myers.

Contact our custom steel fabrication experts today. Together, we will create a safer, more secure environment.