Technology in metal art fabrication is reshaping the way artists and designers turn ideas into reality. CNC cutting, laser engraving, and 3D modeling now allow for precision, complexity, and creative freedom that were once unimaginable. At Spirit Metals, we’ve seen how these tools help artists and builders push boundaries, transforming intricate digital designs into durable and stunning works of art. Whether you’re an artist or a construction professional, learning how these technologies shape modern fabrication is key to staying innovative.

The Evolution of Technology in Metal Art Fabrication

Metal art has come a long way from ancient blacksmiths shaping with fire and hammer. The real revolution occurred in the late 20th century with the advent of computer-controlled systems that could transform digital designs into physical forms. CNC machines offered unmatched precision, laser cutters added intricate details, and 3D modeling software gave artists the ability to refine designs virtually before fabrication. Together, these breakthroughs ushered in a new era where imagination and digital precision work in harmony.

Related: From Concept to Creation: The Process Behind Custom Metal Sculpture Fabrication

3D Modeling: The Digital Canvas for Metal Art

A powerful technology in metal art fabrication is 3D modeling. Programs like Fusion 360, Rhino, and Blender allow artists to explore shapes and structures without material limitations, testing ideas that traditional sketching could never capture.

3D modeling allows you to:

- View designs from any angle

- Apply finishes virtually

- Simulate movement and stress points before cutting metal

Parametric tools ensure that when one design element changes, the rest adjust automatically—saving time and protecting design integrity. Models can transfer directly to CNC machines or laser cutters, creating a seamless path from imagination to fabrication. This digital canvas blends mathematical precision with artistic freedom, making 3D modeling a cornerstone of today’s creative process.

CNC Technology: Precision for Modern Metal Art

CNC technology has redefined precision in metal art. Plasma cutters slice through thick steel with accuracy, while multi-axis milling machines carve sculptural curves and textures directly from digital models.

This technology in metal art fabrication translates digital designs into reality with exact fidelity. Many creators pair CNC precision with hand-finishing to add warmth and individuality, blending machine accuracy with human craftsmanship.

CNC also enables advanced joinery methods such as interlocking puzzle-like components or hidden tab-and-slot systems. These are ideal for both fine art and architectural installations, producing works that are technically feasible, visually striking, and structurally sound.

Laser Engraving and Cutting: Adding Fine Detail

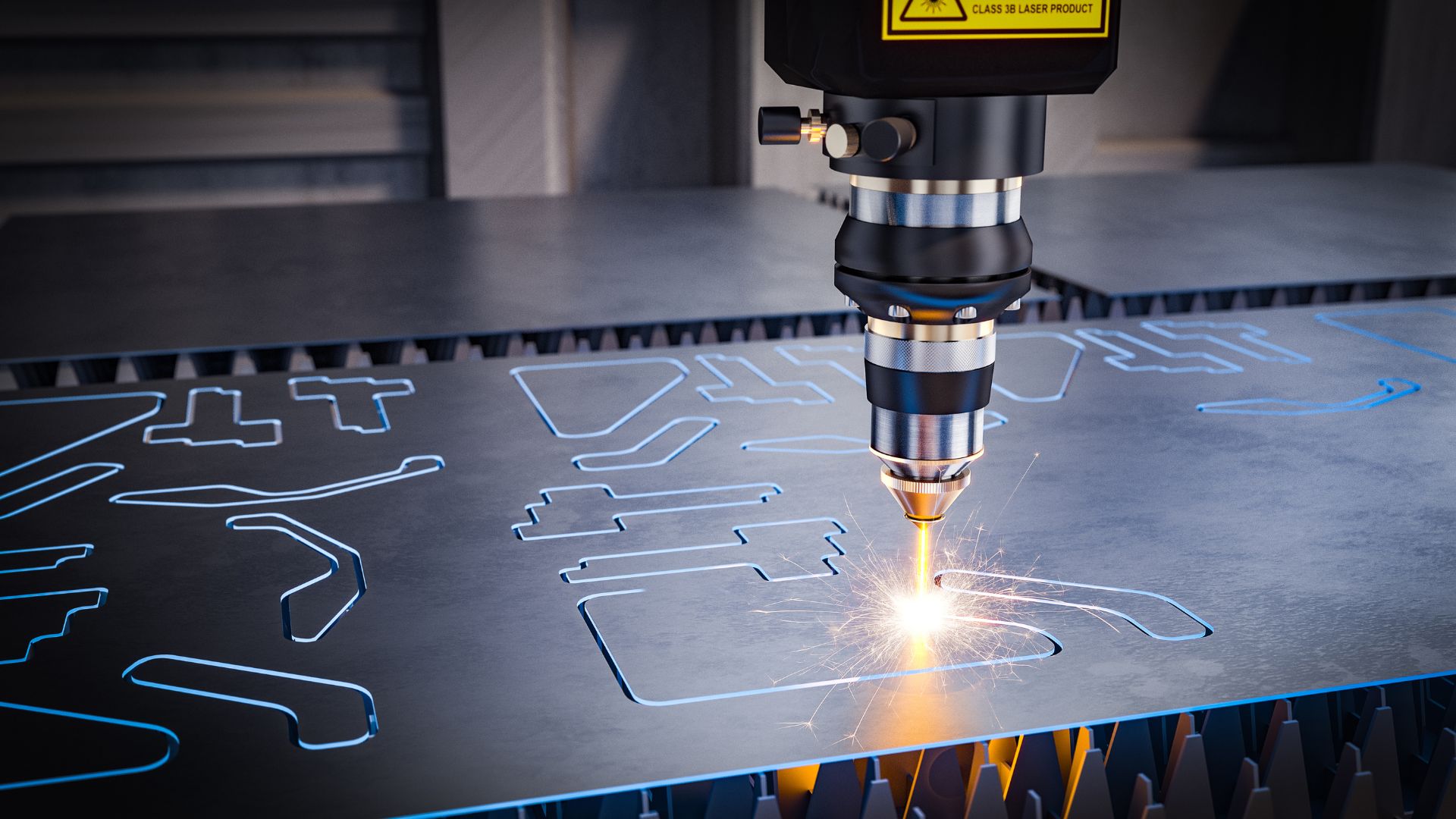

Laser technology in metal art fabrication enables artists to achieve incredible detail that was once thought impossible in steel or aluminum. Fiber lasers engrave imagery, textures, and even subtle color effects, while CO2 lasers cut thin sheet metal with clean, precise edges.

These tools transform metal into a high-resolution canvas. Cuts as narrow as 0.1 mm create lace-like patterns that remain structurally strong, while computer-controlled systems ensure perfect repeatability. For architects and builders, laser engraving can add text, patterns, or signage directly into structural components, combining durability with artistry.

You Might Like: Custom Metalwork for Artists: How Fabricators Bring Your Designs to Life

Combining Technologies: A Seamless Workflow

The most significant advantage of technology in metal art fabrication is the seamless integration of various tools and materials. A sketch can evolve into a 3D model, refined virtually, then produced with CNC cutting and laser engraving—all while keeping the artist’s vision intact.

This integration enables artists to experiment quickly, shifting seamlessly between digital and physical stages without wasting material. Many now develop unique styles by pairing 3D modeling for organic forms, CNC machining for structural elements, and lasers for surface detail—results that are impossible to achieve with traditional methods alone.

Collaboration has also grown. Artists, engineers, and fabricators can share digital files, textures, and component libraries, streamlining even the most complex construction projects. The result: artworks and architectural features fabricated with the same reliability as structural components, but with far greater creative flair.

The Benefits of Technology in Metal Art Fabrication for Artists

While these tools are fascinating on a technical level, their real value lies in how they empower artists. By using technology in metal art fabrication, creators gain:

- Time savings: What once took days—or even weeks—to cut and engrave can today be accomplished within hours.

- Material efficiency: Digital precision reduces waste and lowers costs, making ambitious projects more affordable and accessible.

- Creative freedom: Designs that were previously impossible—organic shapes, intricate patterns, large modular pieces—are now within reach.

- Scalability: Artists can experiment on a small scale, then replicate or scale designs for larger installations without losing detail or accuracy.

For many, these benefits mean spending less time wrestling with technical limitations and more time focusing on artistic innovation.

Digital Fabrication in Public & Architectural Art

3D modeling, CNC cutting, and laser engraving make it possible to create monumental works with the same precision as gallery pieces. Large outdoor sculptures can be optimized for safety while still appearing to defy gravity.

CNC systems handle heavy structural steel as precisely as decorative components, making it easier to blend art into architecture. Modular fabrication enables massive works to be shipped in parts and assembled seamlessly on-site. For buildings, CNC ensures perfect alignment of façades or railings, while lasers add intricate textures or text.

Case Example: Imagine a large public sculpture designed as interlocking components. CNC ensures every piece fits perfectly, while lasers add detailed surface patterns. Once shipped in sections, the work is assembled on-site without compromising artistic vision. This process makes large-scale art both practical and breathtaking.

Accessibility & Democratization

A major impact of technology in metal art fabrication is accessibility. Affordable desktop CNC mills, compact lasers, and intuitive 3D modeling software now give small studios the same capabilities once reserved for industrial shops.

This shift lowers barriers for new artists and helps established ones keep more of their process in-house. Makerspaces and fabrication labs create collaborative spaces where techniques and ideas are shared and exchanged.

Online communities further fuel this trend with tutorials, open-source designs, and global inspiration. Many artists now exchange digital design libraries or textures online, building on one another’s work and accelerating innovation across borders. This global exchange is sparking cross-cultural creativity that blends tradition with cutting-edge tools.

For educators and students, digital tools provide hands-on experiences that bridge the fine arts with practical trades. Spirit Metals supports this growth by supplying materials that serve both creative and industrial needs.

The Future of Technology in Metal Art Fabrication

Emerging innovations promise to expand the possibilities for artists. Artificial intelligence is beginning to generate complex patterns, while hybrid systems combine 3D printing with CNC milling and laser texturing to create entirely new aesthetics.

Metal 3D printing is becoming increasingly accessible, enabling the production of forms with internal structures or variable densities that no other method can replicate.

For architects and builders, these advances mean metal features that are both functional and artistic. Spirit Metals remains committed to supplying materials that support these next-generation techniques while staying grounded in traditional craftsmanship.

Bringing It All Together: The Spirit Metals Advantage

At Spirit Metals, we know how technology in metal art fabrication is reshaping creativity. Our wide range of structural steel and specialty alloys supports a variety of applications, from public sculptures to architectural features.

Our team combines expertise in supply, construction, and engineering to help you choose the right material for CNC cutting, laser engraving, or any modern fabrication process. Our approach is built on trust, accountability, and clear dialogue. making collaboration simple and effective.

Whether you’re an emerging artist testing bold new ideas or an established creator scaling up to large installations, Spirit Metals is here to help.

Contact us today to receive a quote for your next project. Together, we can combine artistic ambition with the precision of advanced fabrication.