Selecting the appropriate structural steel plate types for your construction or fabrication project can significantly impact performance, durability, and cost-effectiveness. As a professional in the commercial building, bridge work, or roadway construction industry, understanding the nuanced differences between various structural steel plate types like A36, AR (Abrasion Resistant), and ABS (American Bureau of Shipping) is crucial for project success.

Spirit Metals is Central Florida’s leading source for local and national contractors navigating these choices and providing the right materials at the promised time.

The Real-World Challenges of Steel Plate Selection

Are your projects facing delays because you’ve specified the wrong plate materials for specific applications? Have you encountered premature wear or structural issues because the plate material wasn’t suited to the operating environment?

You’re not alone. Many construction and fabrication professionals struggle with these common challenges when selecting structural steel plate types:

- Application Uncertainty: Determining whether A36 plate, AR plate, or ABS plate is optimal for specific use cases often requires specialized knowledge that many project managers lack.

- Cost-Performance Balance: Selecting steel varieties that provide necessary performance without unnecessary expense requires understanding the true value proposition of each option.

- Supply Chain Complications: Securing the right steel plate materials within project timelines can be challenging, particularly for less common varieties or projects with specific thickness requirements.

- Specification Confusion: Misinterpreting industry standards for different steel grades can lead to compliance issues and project delays.

- Processing Limitations: Not all A36 plate, AR plate, or ABS plate varieties respond uniformly to cutting, forming, and welding processes, creating fabrication challenges when the incorrect material is specified.

Essential Characteristics of Common Structural Steel Plate Types

Understanding the fundamental properties of different structural steel plate types is the first step in making informed decisions about selection. Each variety offers distinct advantages for specific applications:

A36 Structural Steel Plate

A36 steel plate remains the most commonly used steel plate material in general construction applications. Because of its balanced properties, A36 plate is suitable for a wide range of uses:

Composition and Properties

A36 plate is a carbon steel with a yield strength of 36,000 psi (hence the designation). This makes it strong enough for most structural applications while remaining cost-effective.

Fabrication Characteristics

Among steel plate options, A36 plate offers excellent:

- Weldability: Minimal preheat requirements and good fusion properties

- Formability: Responds well to bending and forming operations

- Machinability: Can be drilled, cut, and processed with standard tools

Typical Applications

A36 steel plate is commonly used for:

- Building columns and beams

- Structural supports

- General fabrication projects

- Equipment bases and frameworks

According to studies by the American Institute of Steel Construction, A36 plate accounts for approximately 60% of all steel used in commercial construction projects due to its versatility and favorable cost-to-performance ratio.

AR Steel Plate

AR steel plate represents a specialized category among structural steel plate types, engineered specifically to withstand severe wear conditions:

Composition and Properties

AR plate is manufactured with a higher carbon content and additional alloying elements, such as chromium and nickel, resulting in hardness ratings typically between 200-500 Brinell. This hardness is the key differentiator from other steel plate materials.

Performance Characteristic

AR plate delivers:

- Wear resistance: Up to 8 times the wear life of standard A36 in abrasive applications

- Impact resistance: Ability to withstand repeated impact while maintaining structural integrity

- Hardness consistency: Uniform properties throughout the material thickness

Common Applications

AR steel plate excels in:

- Mining equipment components

- Material handling systems

- Concrete mixing drums

- Waste handling equipment

- Rock crusher components

- Dump truck beds and hoppers

Research from the Steel Market Development Institute indicates that using appropriate AR plate can extend component life by 300-500% in high-wear applications compared to standard structural steel options.

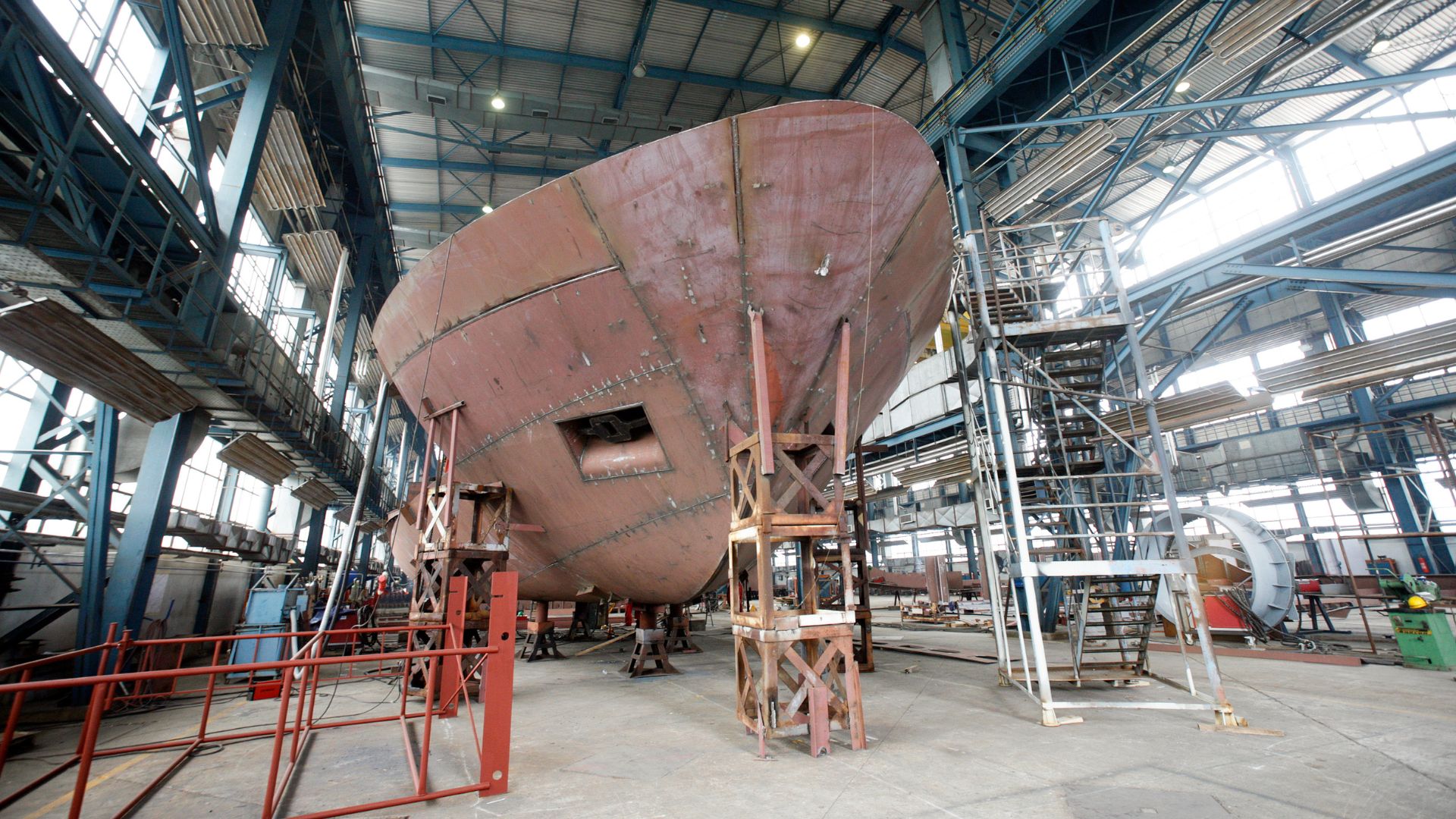

ABS Steel Plate

ABS-certified plate stands apart from other structural steel plate types due to its specialized certification for marine and offshore applications:

Certification Significance

Unlike other plate materials, ABS plate undergoes rigorous testing and certification by the American Bureau of Shipping, ensuring it meets strict standards for marine and offshore applications.

Grade Variations

ABS structural steel plate types include multiple grades:

- ABS Grade A: General purpose hull structural steel

- ABS Grade B: Higher strength hull structural steel

- ABS Grade AH/DH/EH: Higher strength steels with enhanced toughness requirements

- ABS Grade AH36/DH36/EH36: High-strength versions with minimum yield strengths of 36 ksi

Key Characteristics

ABS plate offers:

- Certified toughness: Guaranteed impact properties at specified temperatures

- Consistent quality: Rigorous testing ensures reliability in critical applications

- Traceability: Complete documentation from production through installation

Primary Applications

ABS steel plate is essential for:

- Marine vessel hulls and structures

- Offshore platforms

- Shipbuilding components

- Dock and port structures

- Marine equipment subjected to classification requirements

Critical Factors in Selecting Structural Steel Plate Types

Making the optimal choice between different structural steel plate types requires careful consideration of several key factors:

Operating Environment

The conditions under which the steel will function should drive your selection of appropriate plate material.

- High-wear environments: Generally call for AR plate varieties

- Marine/saltwater exposure: Typically requires ABS-certified plates

- General construction: Often well-served by standard A36 steel plates

Load Requirements

Different steel varieties offer varying levels of strength.

- Static loads: May be adequately served by A36 plate

- Dynamic loads: Might require higher-strength steel grades

- Impact loading: Often best addressed with AR plate varieties

Fabrication Methods

Consider how the material will be processed during manufacturing.

- Extensive welding: Some steel grades maintain properties better in heat-affected zones

- Complex forming: Certain varieties offer better formability

- CNC processing: Some plates machine more efficiently than others

Cost Considerations

Balance initial material costs against lifecycle value.

- Material pricing: Standard A36 plate is typically the most economical of these steel options

- Replacement frequency: The higher initial cost of specialized plate may be offset by longer service life

- Fabrication expenses: Some steel varieties require more labor-intensive processing

You Might Like: Keys to Selecting The Right Diamond Plate Thickness

Common Applications for Different Structural Steel Plate Types

Understanding typical usage patterns can help guide your selection of steel plate materials for specific projects:

Building and Construction Applications

The construction industry uses various structural steel plate types according to specific requirements:

Structural Frameworks

A36 plate is most commonly used for:

- Building columns and connection plates

- Base plates for structural supports

- Stiffeners and gusset plates

- Equipment mounting pads

High-Traffic Areas

AR plate may be specified for:

- Loading dock impact plates

- Chute linings in waste management systems

- Floor plates in heavy industrial environments

- Material transfer points subject to abrasion

Waterfront Structures

ABS-certified steel plate is often required for:

- Marina structural components

- Port facility structures

- Waterway control structures

- Commercial dock systems

Transportation and Infrastructure Projects

Different steel plate varieties serve specific functions in transportation infrastructure:

Bridge Components

Depending on the application:

- A36 plate for general structural elements

- Higher-strength steel grades for critical load-bearing members

- ABS plate for bridges with marine vessel clearance requirements

Highway Systems

Various steel materials used in:

- Guard rail backing plates

- Sign structure foundations

- Sound barrier structural supports

- Expansion joint systems

Railway Infrastructure

Different plates specified for:

- Track switch components (often AR plate for wear resistance)

- Bridge support structures

- Loading/unloading facilities

- Maintenance equipment components

Fabrication Considerations for Different Structural Steel Plate Types

Each category of steel plate presents unique fabrication challenges and requirements:

Welding Considerations

Proper procedures vary significantly between steel varieties.

- A36 plate: Generally requires minimal special procedures

- AR plate: Often needs preheat, specific filler metals, and heat input control

- ABS plate grades: Must follow certified welding procedures to maintain certification

Cutting Methods

Different steel plate materials respond differently to thermal cutting.

- Flame cutting: Heat-affected zone varies between grades

- Plasma cutting: Speed and quality vary by material

- Waterjet cutting: May be preferred for certain high-hardness varieties

Forming Operations

Bending force requirements differ substantially.

- Bend radius: Minimum radius varies significantly between steel grades

- Springback compensation: More critical with higher-strength varieties

- Equipment capacity: Higher-strength plates require greater tonnage

Heat Treatment

Post-fabrication heat treatment requirements vary by type.

- Stress relief: Critical for some steel varieties after extensive welding

- Normalization: May be required to restore properties in heat-affected zones

- Property verification: Testing may be needed to confirm properties are maintained

How Spirit Metals Supports Your Structural Steel Plate Requirements

As a leading supplier of structural steel plate types throughout Florida, Spirit Metals offers comprehensive support for your project needs:

- Material Selection Guidance: Our team helps you navigate the complexities of choosing between steel plate options based on your specific application requirements.

- Quality Assurance: All our steel materials are sourced from reputable mills with complete certification and testing documentation.

- Inventory Availability: We maintain extensive stocks of common plate varieties in various thicknesses to meet immediate project needs.

- Custom Processing: In addition to supplying raw materials, we can provide steel plates cut to your specifications, thereby reducing your fabrication time and costs.

- Technical Support: Our expertise with structural steel plate types extends beyond supply to include application-specific technical guidance throughout your project lifecycle.

- Reliable Delivery: We understand that timely delivery of quality steel is critical to project schedules, which is why we offer dependable logistics throughout our Florida service area.

Conclusion: Making Informed Decisions About Structural Steel Plate Types

Selecting the appropriate plate varieties for your specific application requires balancing numerous factors, including performance requirements, fabrication considerations, and budget constraints. By understanding the fundamental differences between A36 plate AR plate, and ABS plate varieties, you can make informed decisions that optimize both initial costs and long-term performance.

For your next project requiring structural steel plate, remember that material selection should be a strategic decision made early in the planning process. By consulting with knowledgeable suppliers like Spirit Metals, you can ensure you’re specifying the right steel plate materials for your specific application, avoiding costly mistakes and performance issues down the road.

Are you ready to discuss your structural steel plate requirements? Contact Spirit Metals today and let our team of experts help you select the perfect materials for your next construction or fabrication project.